The Gear-Lift® Rack and Pinion gear drive Vertical Reciprocating Conveyor (VRC) system is designed for industrial use in rugged environments. Our Gear-Lfit® VRC uses a gear drive rather than standard cables or chains. The system uses Dual Pinion Gear Drives with Dual Automatic Brakes, which ride on a Guide Rack and Rail system.Gear-Lift® models are available in several different sizes and load capacities; ranging from small single purpose automation lifts to large capacity industrial machines.

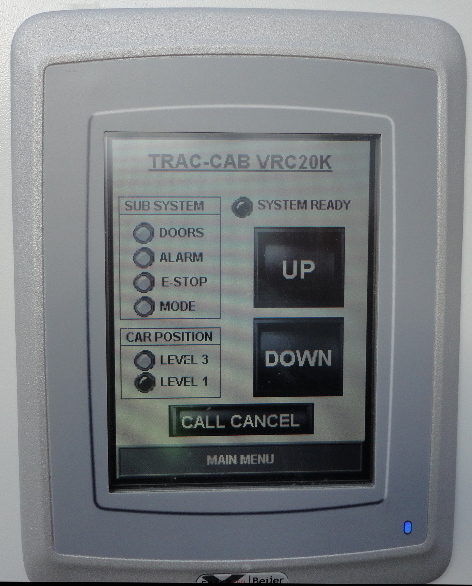

The Trac-Cab GearLift VRC20K is a Rack and Pinion Industrial VRC designed and engineered for industrial applications in harsh environments. The Code classification for the VRC20K system is a Vertical Reciprocating Conveyor (VRC) as defined by the ASME B20.1 Safety Standard for Conveyors and Related Equipment Code. The machine travels up and down the VRC Guide System using dual pinion gear drives, driven by a variable speed electric drive system. The dual pinions each have a fully redundant integral automatic fail-safe brake system in addition to the TESI GearLock system for maximum safety. The dual pinion gears engage a Rack and Rail system engineered to meet the VRC Code requirements. The Rack and Rail runs the height of the structure providing precision tracking and positive engagement.

The benefits of using a TESI designed Rack and Pinion drive VRC are very significant when compared to the other established mechanical methods of lifting. Rack and Pinion drive is a direct gear tooth engagement insuring no hang-ups or tangled cables. Other systems use a secondary lifting apparatus, such as a winch cable or chain, which are more difficult to inspect and maintain. Additionally, we are using a GearLock safety locking system which ensures that our machine stops and holds no matter what; it cannot “free wheel” by design, so there is no worry about a broken cable or chain letting the platform fall. This is much safer than relying on a mechanical “dog” or chain grab for a safety system, which should, but might not engage and could break if the shock is too great. Rack and Pinion drive has been proven safer in elevator applications, has a longer useful life, and is easy to maintain making it the most cost efficient value for the customer. “When you want the safest lift and long term value for your capital investment, Rack and Pinion drive is the best choice.